In today’s fast-paced industrial landscape, businesses are constantly searching for ways to maximize efficiency, minimize errors, and enhance productivity. One of the most transformative trends in this domain is the adoption of industrial units with advanced automation systems. These systems are no longer a futuristic concept—they are the backbone of modern manufacturing and industrial operations.

Automation in industrial units refers to the use of technology and machinery to perform tasks that were traditionally handled by humans. Advanced automation systems go beyond basic mechanization. They integrate robotics, artificial intelligence, Internet of Things (IoT) devices, and data analytics to streamline operations.

By incorporating these technologies, industries can achieve higher precision, faster production times, and improved consistency across operations. From automotive assembly lines to food processing units, advanced automation has become indispensable.

One of the most compelling advantages of automated industrial units is the significant boost in productivity. Machines can operate continuously without fatigue, ensuring production targets are met faster than manual processes.

Human error is a major concern in industrial production, leading to defects, wastage, and rework. Automation minimizes these errors by standardizing tasks with precision.

Although implementing advanced automation systems requires initial investment, the long-term savings are substantial. Companies benefit from lower labor costs, reduced wastage, and optimized resource utilization.

Industrial environments often involve hazardous conditions. Automation reduces the need for humans to perform risky tasks, improving workplace safety.

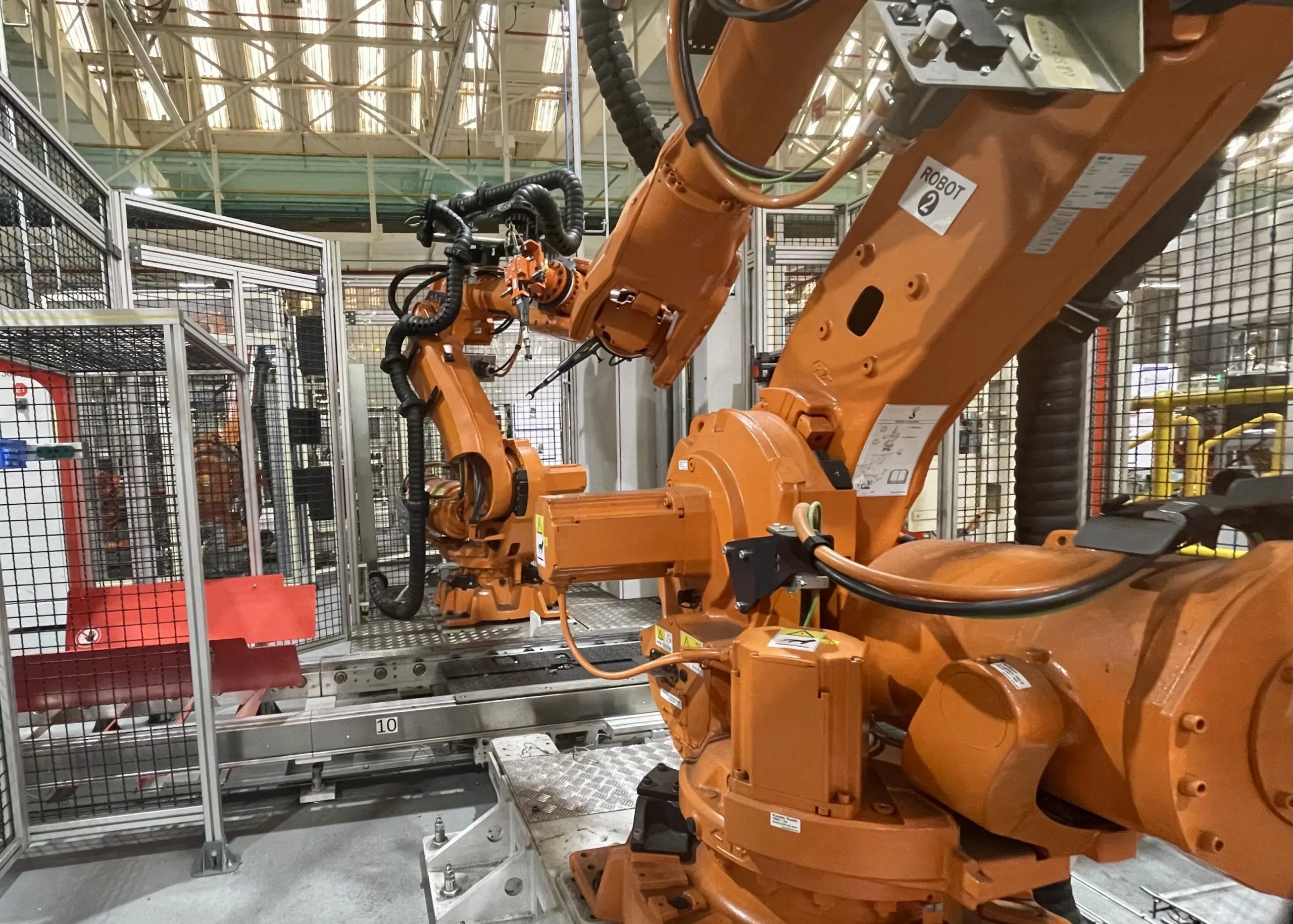

Robots are the most visible aspect of automation. Modern industrial robots are versatile and capable of handling tasks like welding, painting, assembly, and material handling.

AI algorithms optimize production schedules, predict equipment failures, and analyze large datasets to enhance efficiency. Machine learning allows systems to adapt over time, improving performance without human intervention.

IoT devices connect machinery, sensors, and control systems to create a networked environment. Real-time data collection allows industries to monitor production processes, detect anomalies, and make informed decisions.

HMI systems enable operators to interact with machines efficiently. They simplify complex processes, making it easier to control production and access performance metrics.

The automotive sector has been a pioneer in adopting advanced automation. Robotic arms handle welding, painting, and assembly, while AI systems monitor production lines for errors. This results in faster production cycles and improved vehicle quality.

Automation ensures hygiene, precision, and speed in food processing. Robotic systems handle packaging, sorting, and quality control, reducing human contact and contamination risks.

Precision is critical in pharmaceutical production. Automated systems ensure accurate formulation, packaging, and labeling while complying with strict regulatory standards.

The production of smartphones, semiconductors, and other electronics relies heavily on automation. Advanced systems perform intricate assembly and testing tasks, ensuring minimal defects and high efficiency.

While the benefits are clear, industrial automation is not without challenges. Companies must consider initial investment costs, employee training, and potential resistance to change.

The future of industrial units lies in smart factories, where automation, AI, and IoT converge to create fully optimized production ecosystems.

Transitioning to advanced automation requires careful planning and strategy.

Many leading companies worldwide have transformed their operations through automation. For instance, automotive giants have reduced assembly time significantly while improving vehicle quality. Food processing plants have minimized contamination risks and increased packaging speed. Electronics manufacturers have achieved precision assembly at a scale impossible with manual labor.

These examples demonstrate that automation is not just a trend but a necessary evolution for industries aiming to stay competitive.

Industrial units with advanced automation systems are redefining the way businesses operate. They offer unmatched efficiency, quality, safety, and cost-effectiveness. While challenges exist, the potential benefits far outweigh the obstacles. Companies that embrace this technological shift are better positioned to thrive in an increasingly competitive global market.

The key takeaway is clear: automation is not just an investment in machinery—it is an investment in the future of industrial growth. Businesses that act now will reap the rewards of improved operations, higher profitability, and sustained competitiveness.

Do Follow Estate Magazine on Instagram

High-ROI Office Spaces Near Dubai Free Zones: Complete ROI Guide